The challenge

For conventional hot or cold repairs, e.g. on casting ladles and covers, a time of roughly one day is required, plus about 1 to 1,2 tons of repair material.

The solution

With REFRASPRAY® refractory concretes, the unavoidable intermediate repairs are now possible without having to let the plant cool down first. The plant continues to be available, and productivity remains stable.

Only a peristaltic pump is required for spray application, and for trowelling work, the material is prepared in a normal mixer.

Energy and

time saving

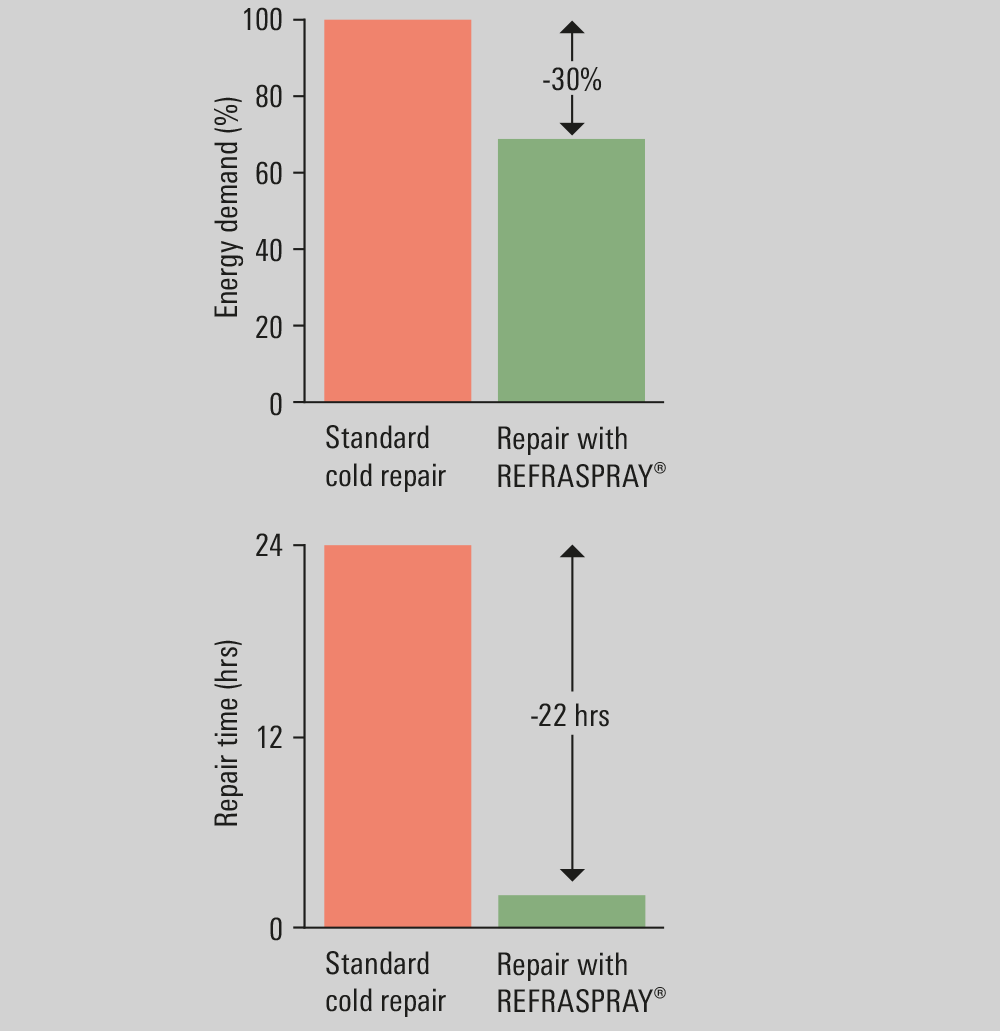

REFRASPRAY® makes intermediate repairs possible, without the need to let the plant cool down first. For the customer, this results in up to 30% lower energy consumption.

REFRASPRAY® enables the repair time to be cut from a whole working day to less than 2 hours.

Advantages at a glance

- up to 30% energy saved during re-commissioning

- simple and safe application

- plant does not have to cool down

- repair time only about 2 hours