Two is not always better

Problems faced with 2-layer linings:

- Complex installation

- Long installation times

- High material consumption & costs

- Loosening of lining & acollapse

The solution:

1-layer lining

With REFRALUSIT® ES, it is possible now to benefit from an option with the lowest thermal heat losses combined with the mechanical resistance of a 1-layer lining.

A unique product concept:

- Simple installation

- Up to 40 % faster installation

- Reduced material consumption

And all this with a comparable shell temperature

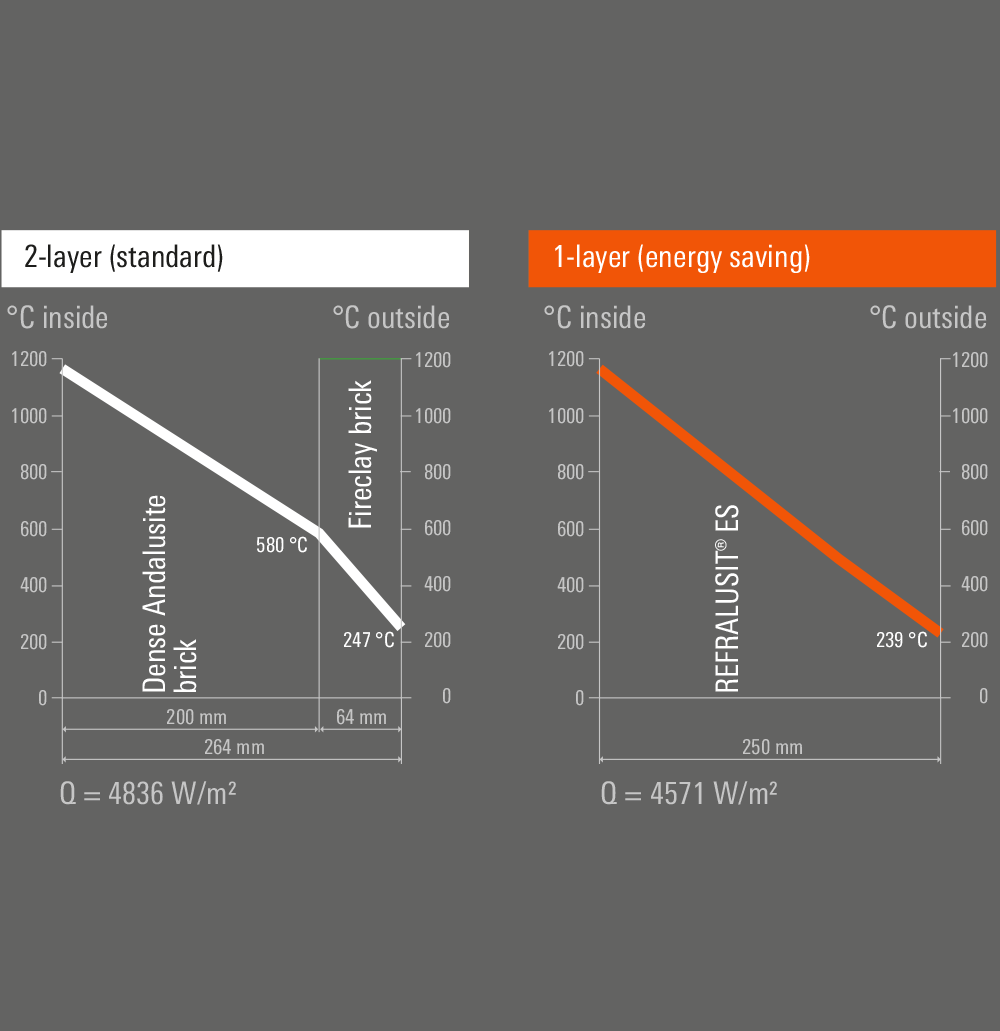

Comparison of

1-layer and 2-layer linings

REFRALUSIT® ES offers the unique possibility of installing a 1-layer Andalusite lining in the burning and calcining zone, because conventional Andalusite bricks would lead to a roughly 30 % higher shell temperature, which previously prohibited their use.

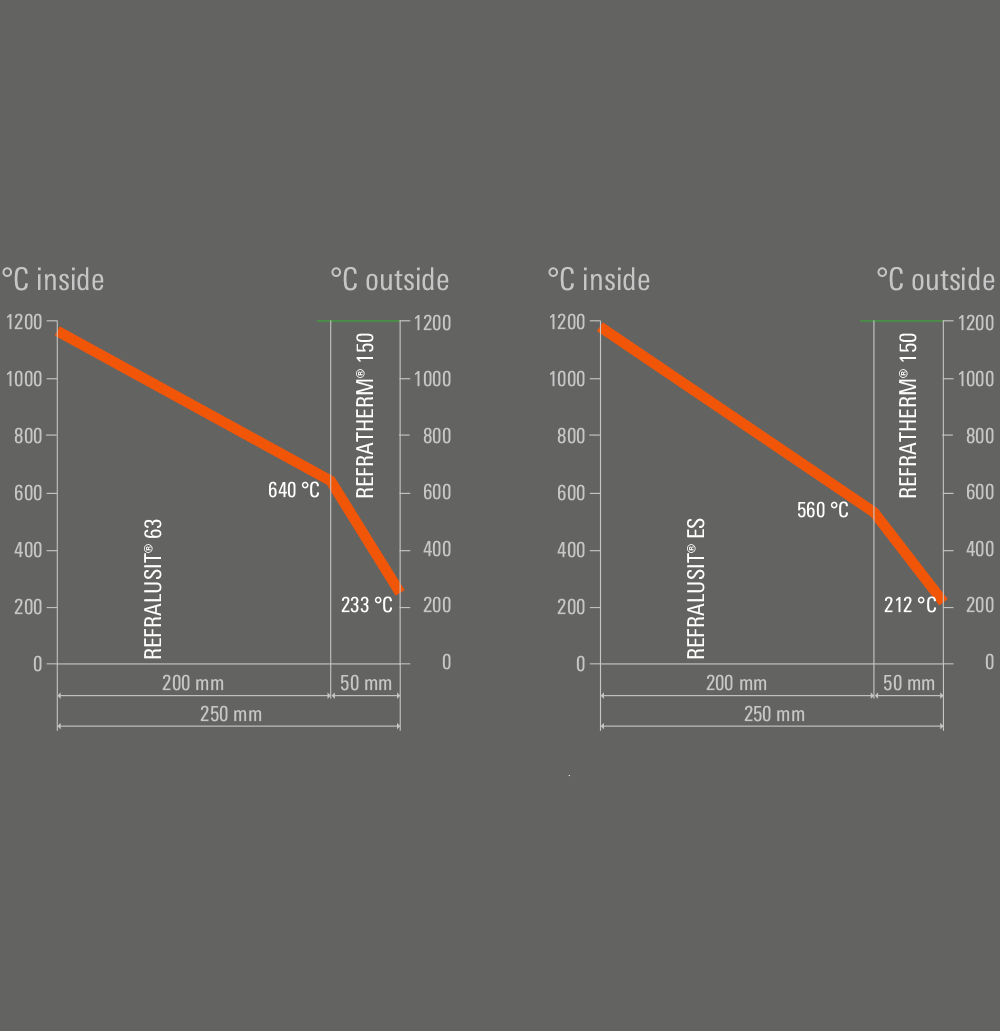

And finally: The coolest part

If the focus is a reduction of the shell temperature with a 2-layer lining, REFRALUSIT® ES is the best choice.

Thanks to the innovative ES technology – which is used in an alumino-silicate brick for the first time – a combination of REFRATHERM® 150 with the unique properties of REFRALUSIT® ES enables the shell temperature to be reduced by about 10 %.

Advantages at a glance

- REFRALUSIT® ES helps to reduce thecarbon footprint

- The 1-layer lining concept makes installation easier

- Up to 40% faster lining installation (1-layer lining)

- Lowest heat losses – both with 1-layer and 2-layer linings

- Reduced lining weight and therefore kiln load

- Reduced transport costs and import duties

- Higher performance achieved by a thicker wear lining

- Reinforced sinter bonding and a finer structure lead to higher strengths and an up to 25 % lower heat flow