Energy management at Refratechnik

Energy efficiency plays an important role along the entire value-added chain.

With a certified energy management system according to ISO 50001:2011 in every European location of the Refratechnik Group, we continuously ensure the systematic, resource-conserving, energy-saving, safe, and economical supply and use of energy. For this, we use modern software solutions to monitor, analyse, and assess energy consumption.

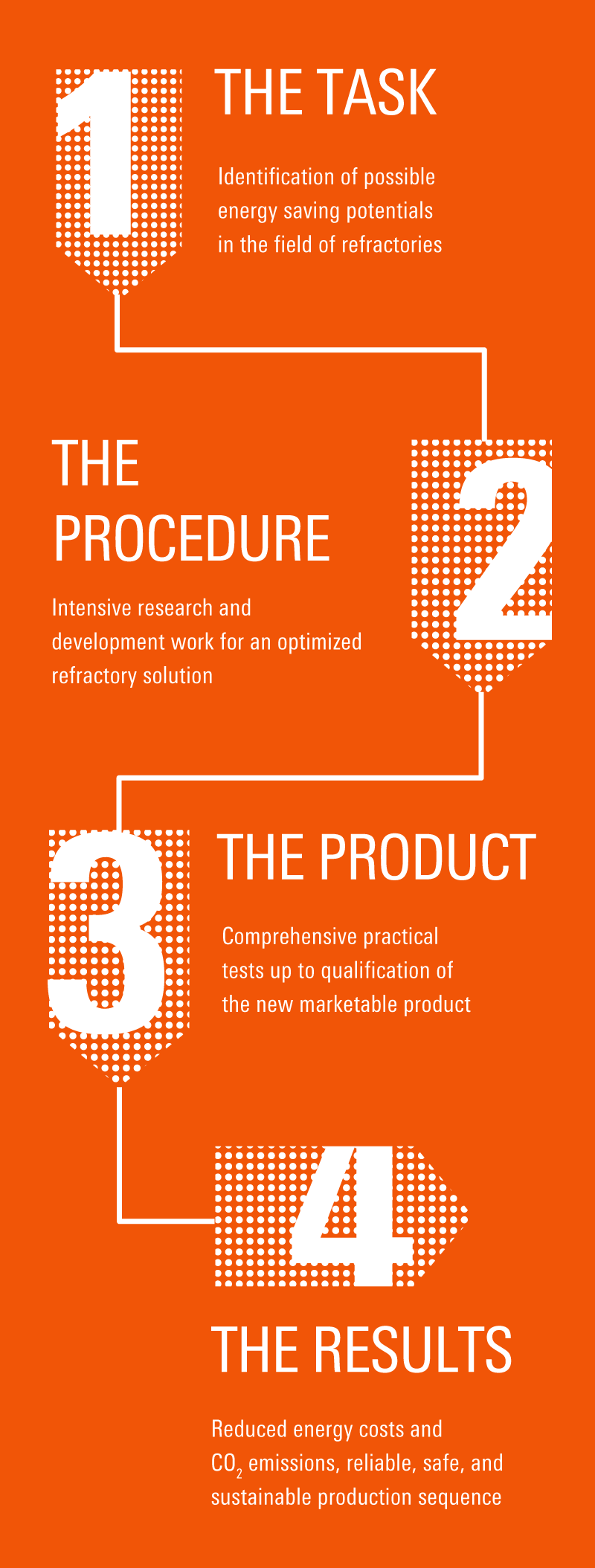

Energy saving in series

Today, energy efficiency is a decisive factor for future economic and ecological developments in the basic industries. Moreover, the global operators of these facilities must ensure that technical stability and sustainability are harmonized along the entire production chain.

As the world‘s leading refractory producer, we have found an answer for this challenge: The ES-Series – optimised refractory solutions for energy-intensive heat-up, smelting or combustion processes that have an astounding energy-saving effect.

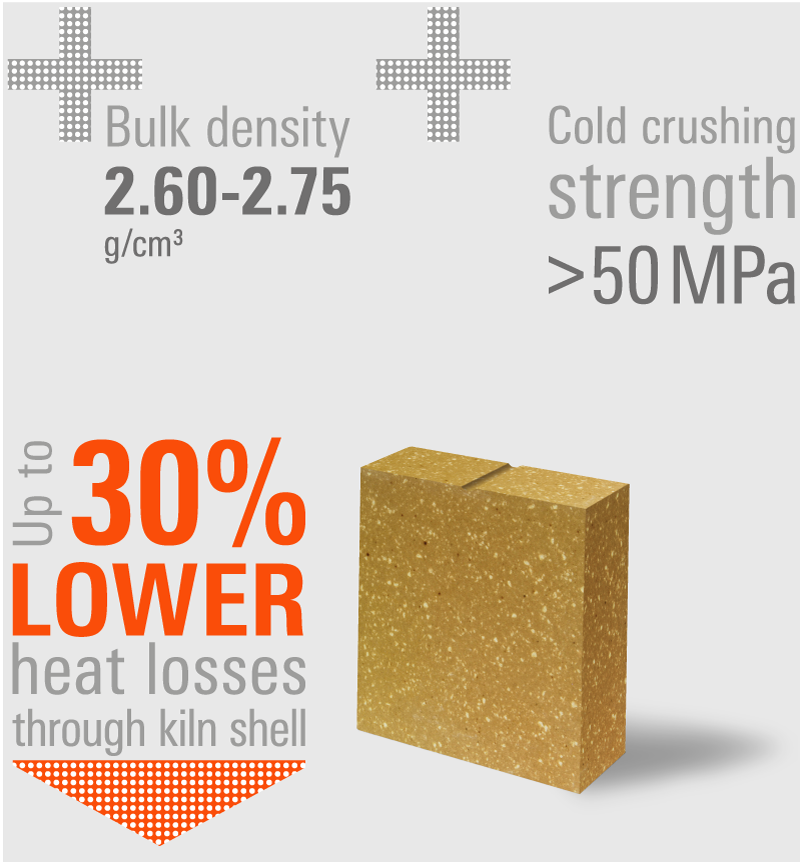

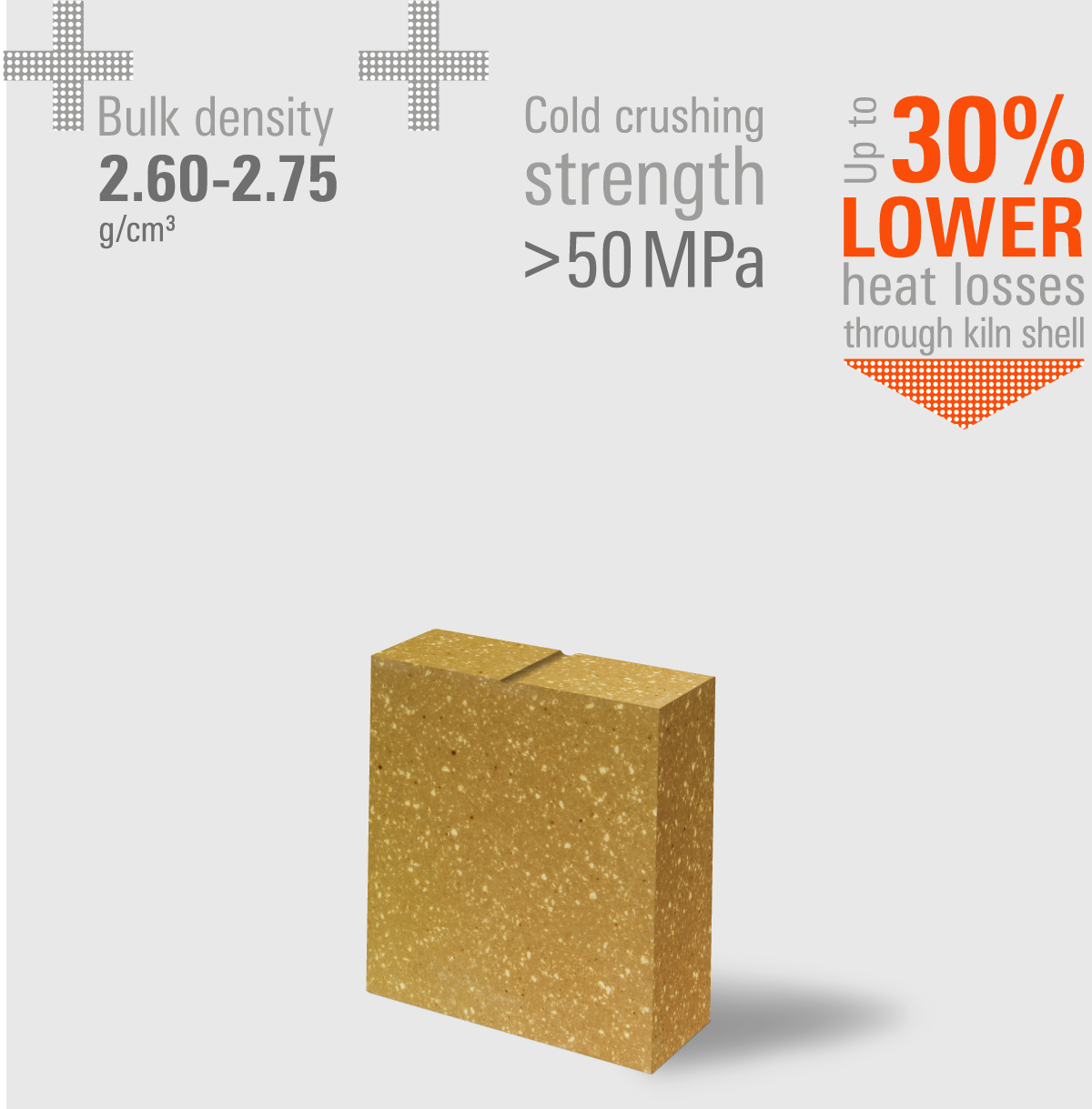

ALMAG® ES

The new concept for a magnesia spinel brick.

With the development of ALMAG® ES – a new magnesia spinel brick – we succeeded in combining higher porosity, lower gas permeability, and high strength. This ensures good thermomechanical and thermochemical resistance. In addition, there are clear benefits in terms of energy efficiency.

- up to 30% lower heat losses through kiln shell

- same performance range as ALMAG® 85

- low thermal conductivity

- reduced overall weight of the refractory lining

- reduced kiln shell temperature

Cement, Lime

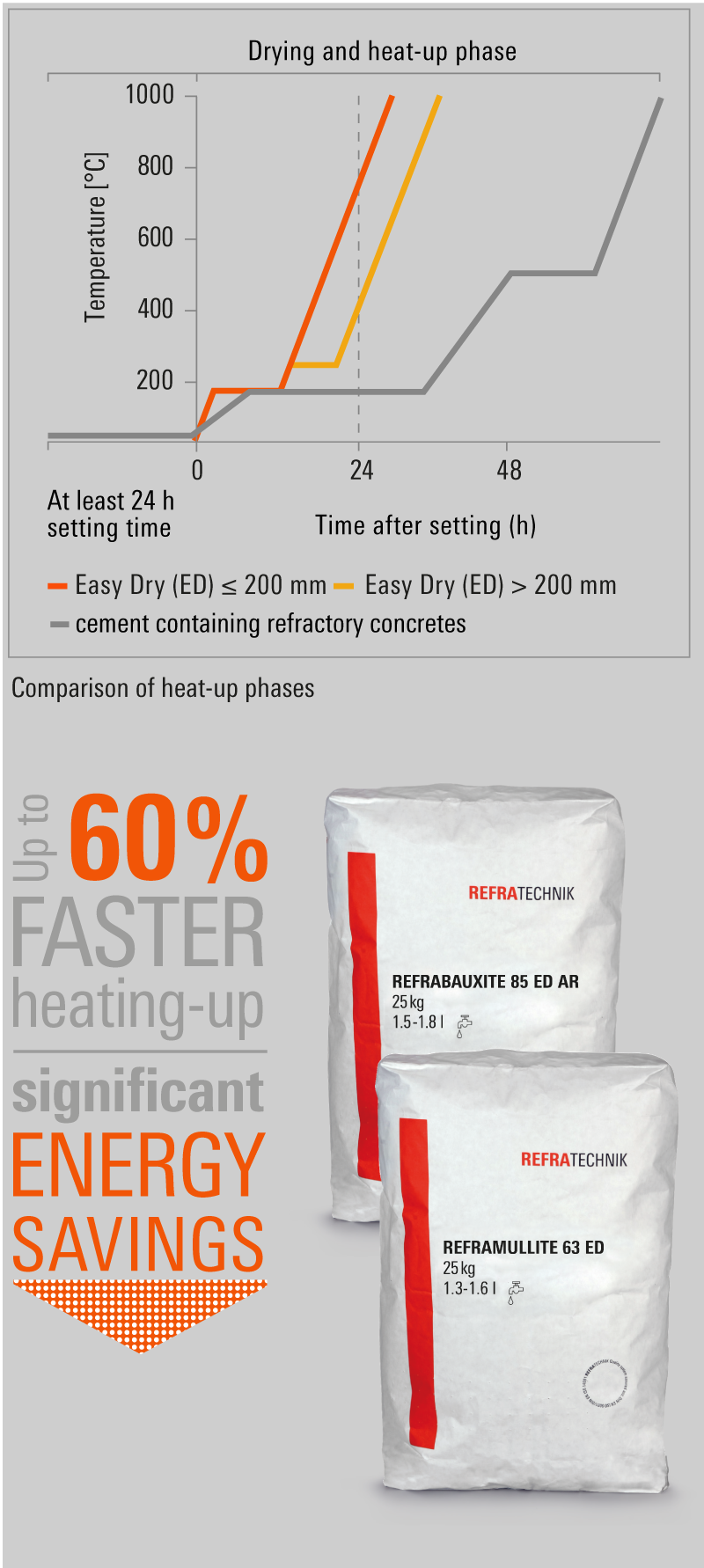

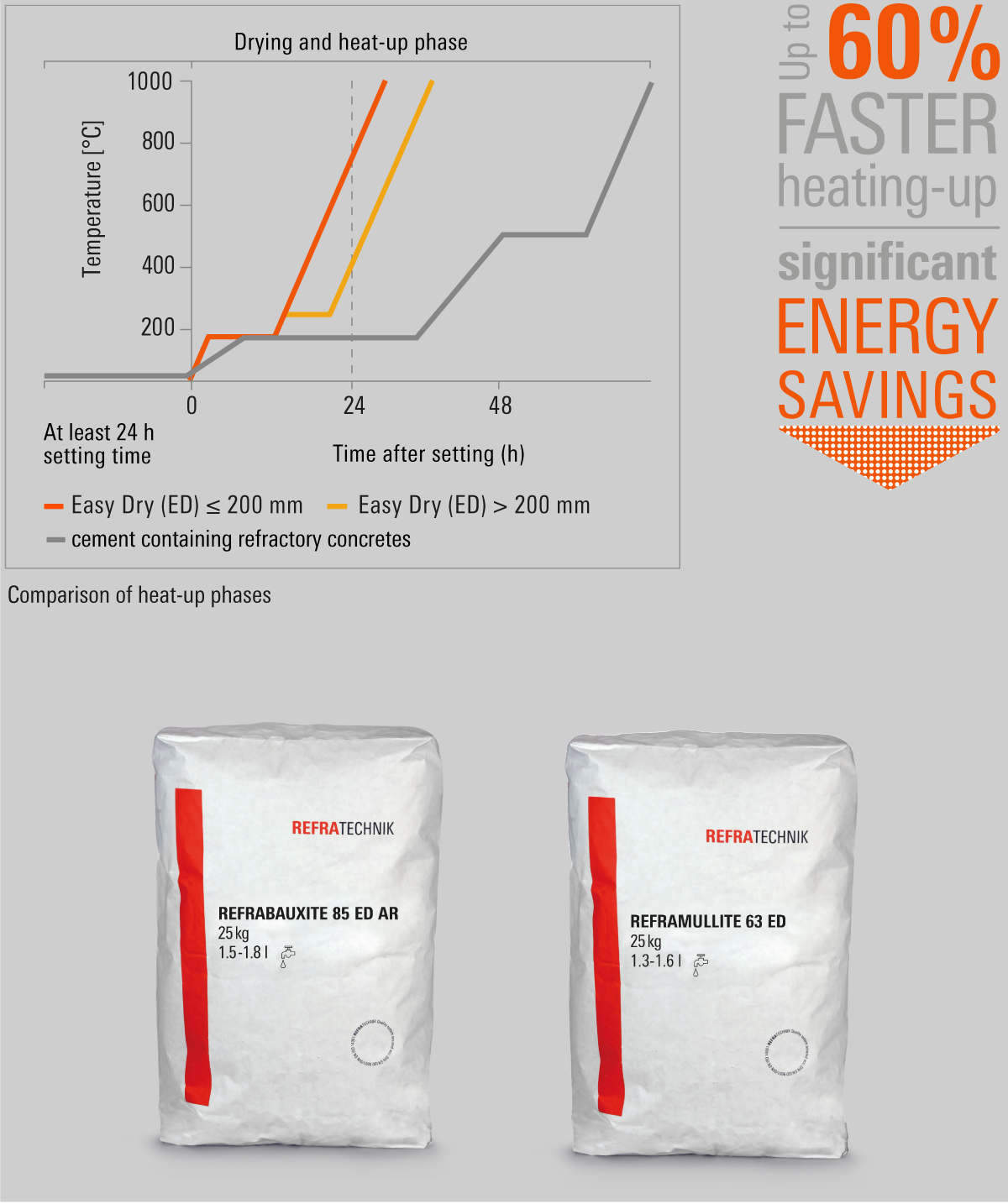

Easy Dry (ED)

refractory technology

Quality and reliability – today and tomorrow.

Easy Dry (ED) refractories are a new development from Refratechnik, with convincing results in everyday use as a result of exhaustive tests.

Suitable for all installation methods, Easy Dry products can be used for refractory lining of every static area in a cement or lime plant, including kiln inlet and discharge zones.

- significant energy savings

- up to 60% faster heating-up and re-commissioning of the plant

- simple storage and unproblematic handling

- clearly reduced wear of equipment

Cement, Lime

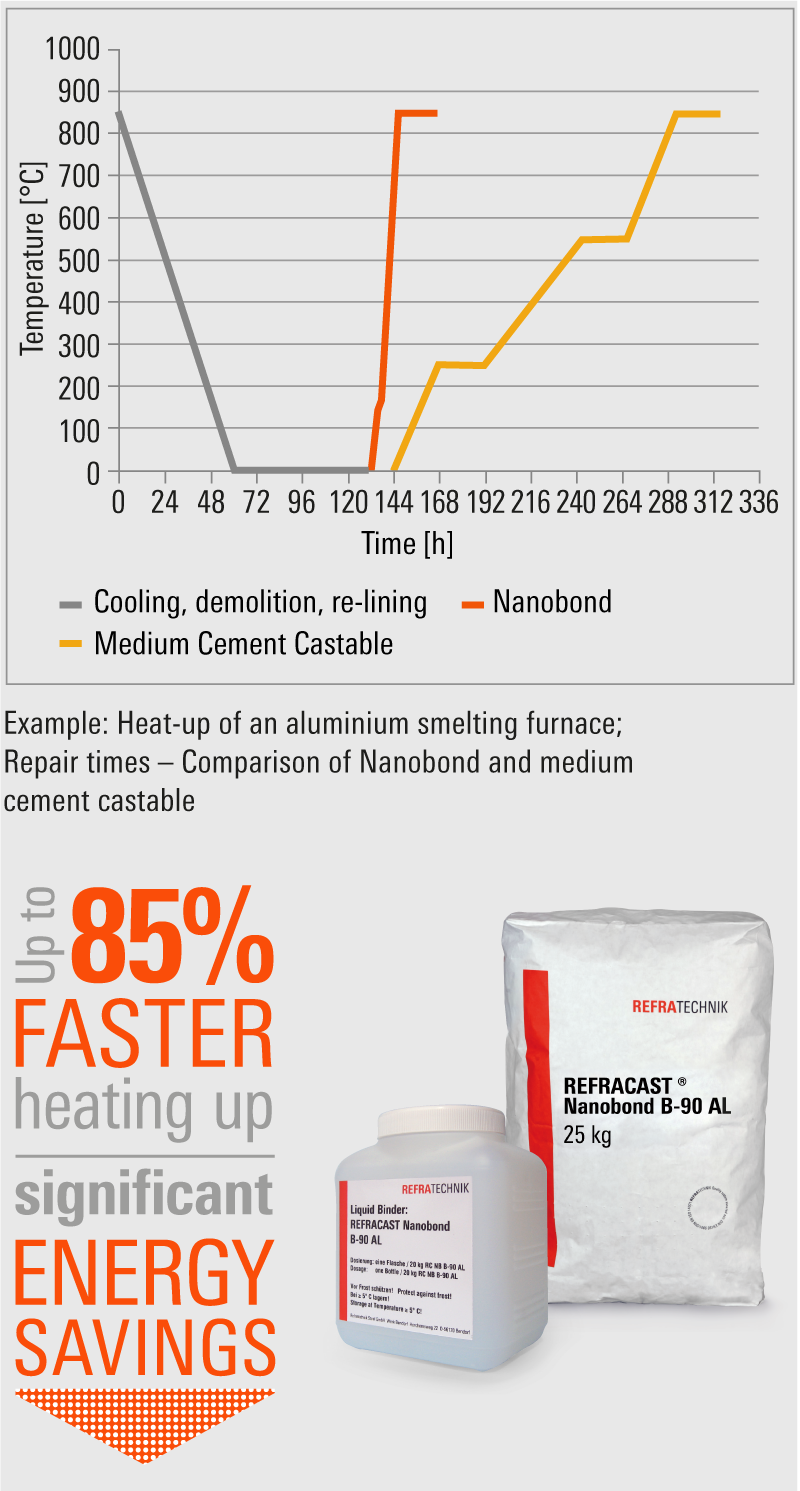

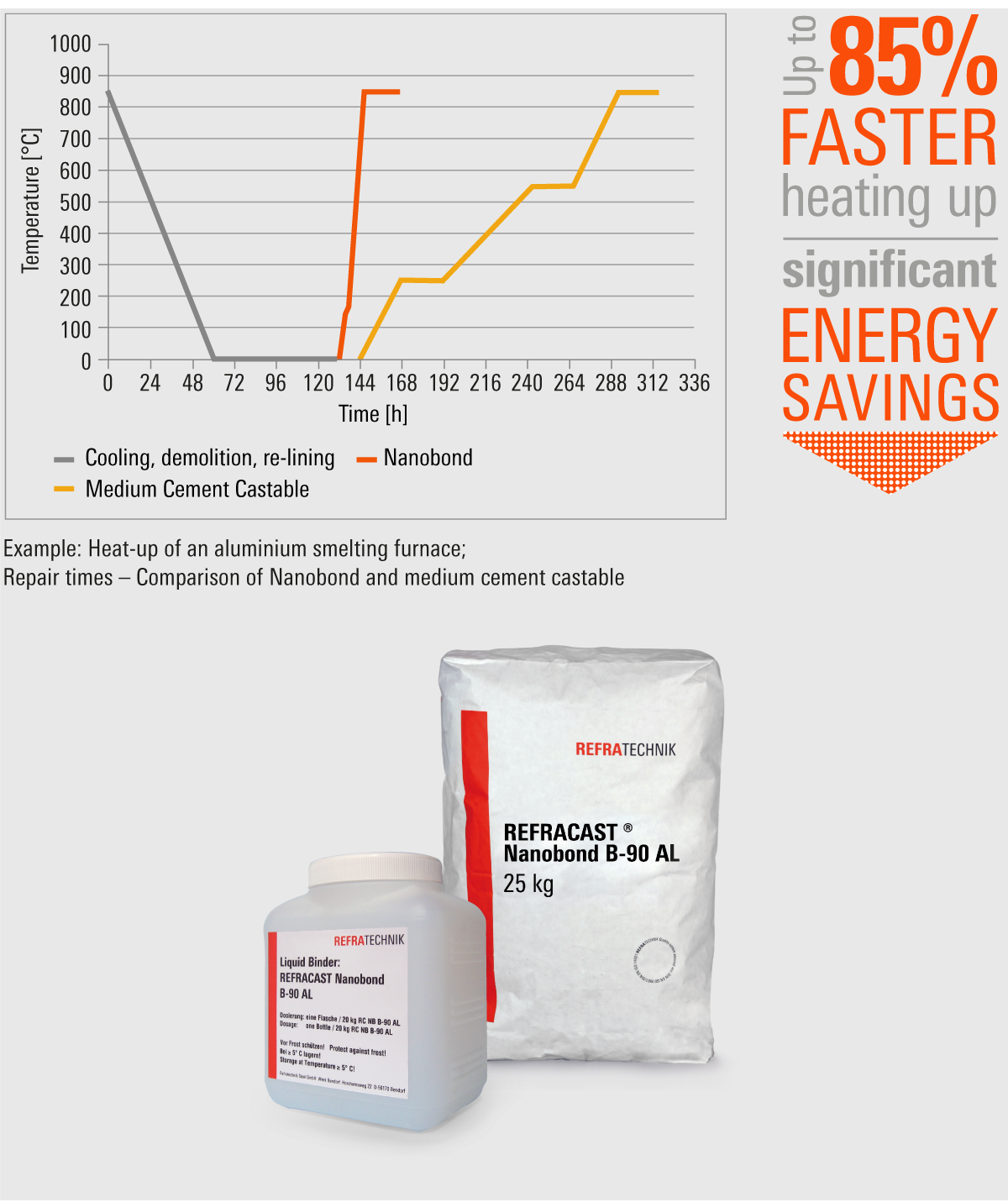

Nanobond

refractory concrete technology

The next generation of monolithic refractory technology.

The Nanobond product range is a new generation of refractory concretes that is insensitive to fast heating up. This results in significant savings in time, energy, and costs.

Moreover, the adherence to other materials is excellent. Overall, Nanobond products are easy to process.

- significant energy savings

- heat-up rates of 50 up to 100 °C/h are possible

- this permits up to 85% faster heat-up time

- high thermal resistance for reliable production processes

- unproblematic storage life up to 12 months

Industrial sectors:

Cement, Lime, Steel, NF-metals, Aluminium, Others

REFRASPRAY®

The fast and lasting solution for hot and cold repairs.

With REFRASPRAY® refractory concretes, the unavoidable intermediate repairs are now possible without having to let the plant cool down first. The plant continues to be available, and productivity remains stable.

Only a peristaltic pump is required for spray application, and for trowelling work, the material is prepared in a normal mixer.

- up to 30% energy saved during re-commissioning

- simple and safe application

- plant does not have to cool down

- repair time only about 2 hours

Industrial sectors:

Steel, NF-metals, Aluminium, Others

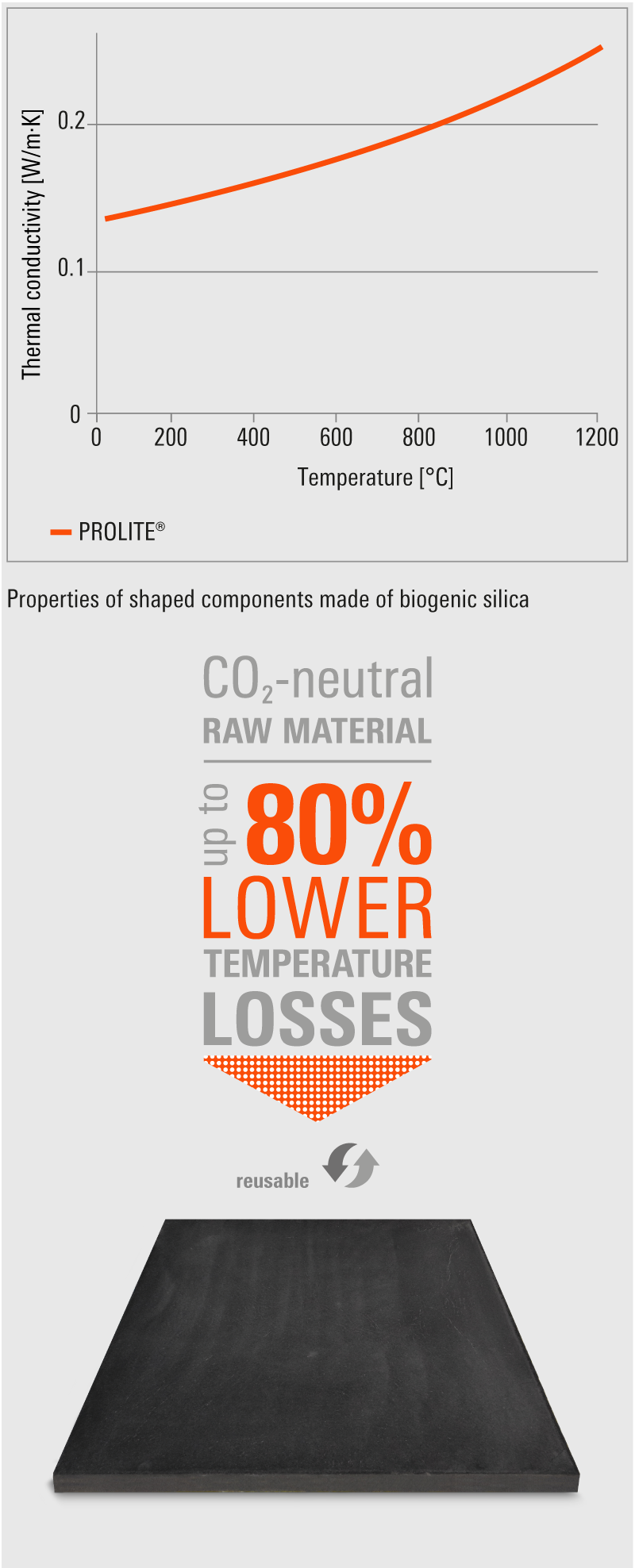

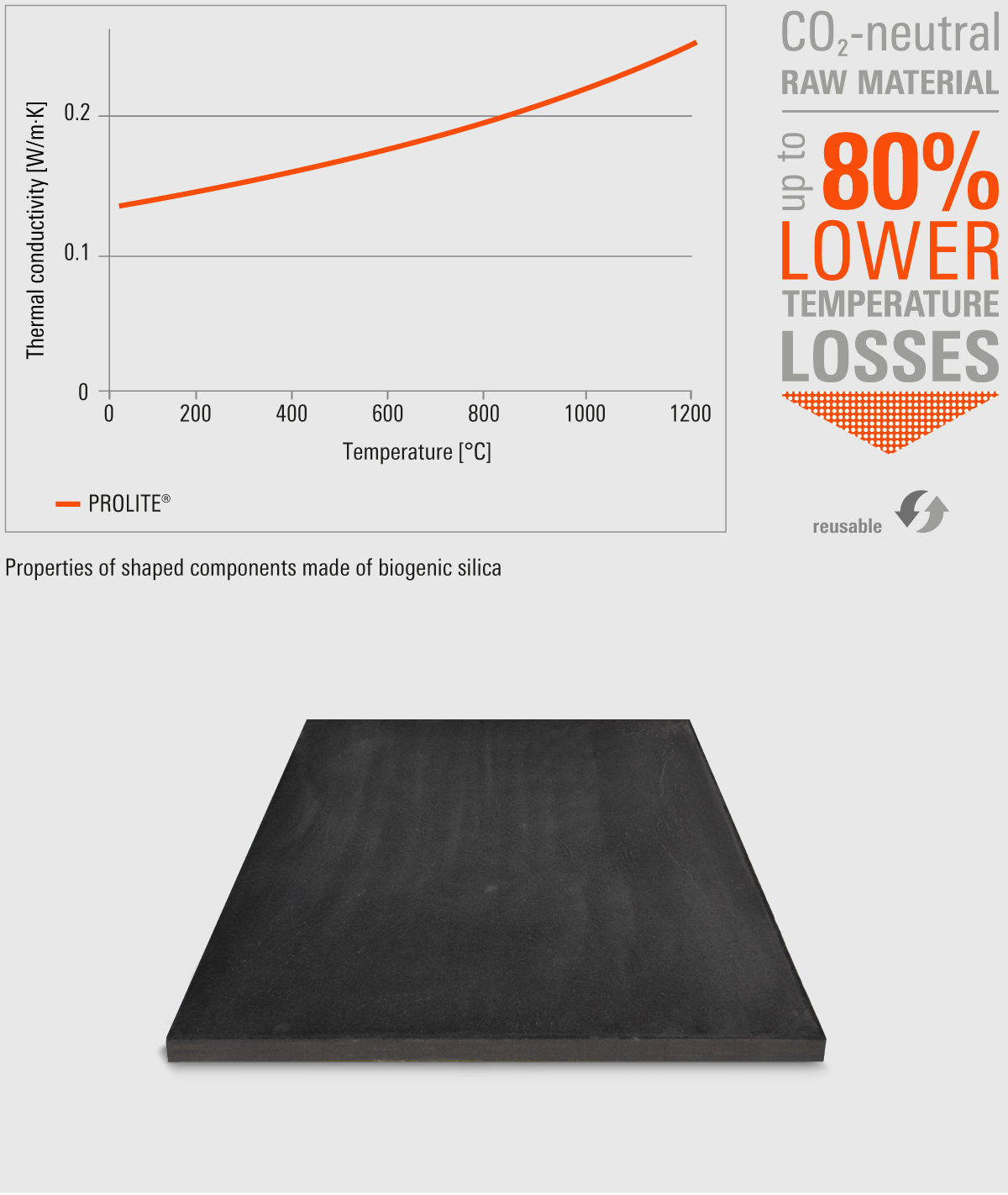

PROLITE®

Optimum insulation with shaped components of biogenic silica.

Shaped components made of biogenic silica as temporary, dust-free insulation in direct contact with hot media

Available as shaped panels, this products combine the outstanding insulating properties of biogenic silica with dust-free and reusable or permanent use. The highly insulating panels are suitable for use in a wide range of industrial applications.

- up to 80% lower temperature losses

- 100% natural and renewable raw material

- high micro-porosity for excellent insulating properties

- applicable with temperatures up to 1600 °C

- suitable for a wide range of industries and applications

Industrial sectors:

Cement, Lime, Steel, NF-metals, Aluminium, Others

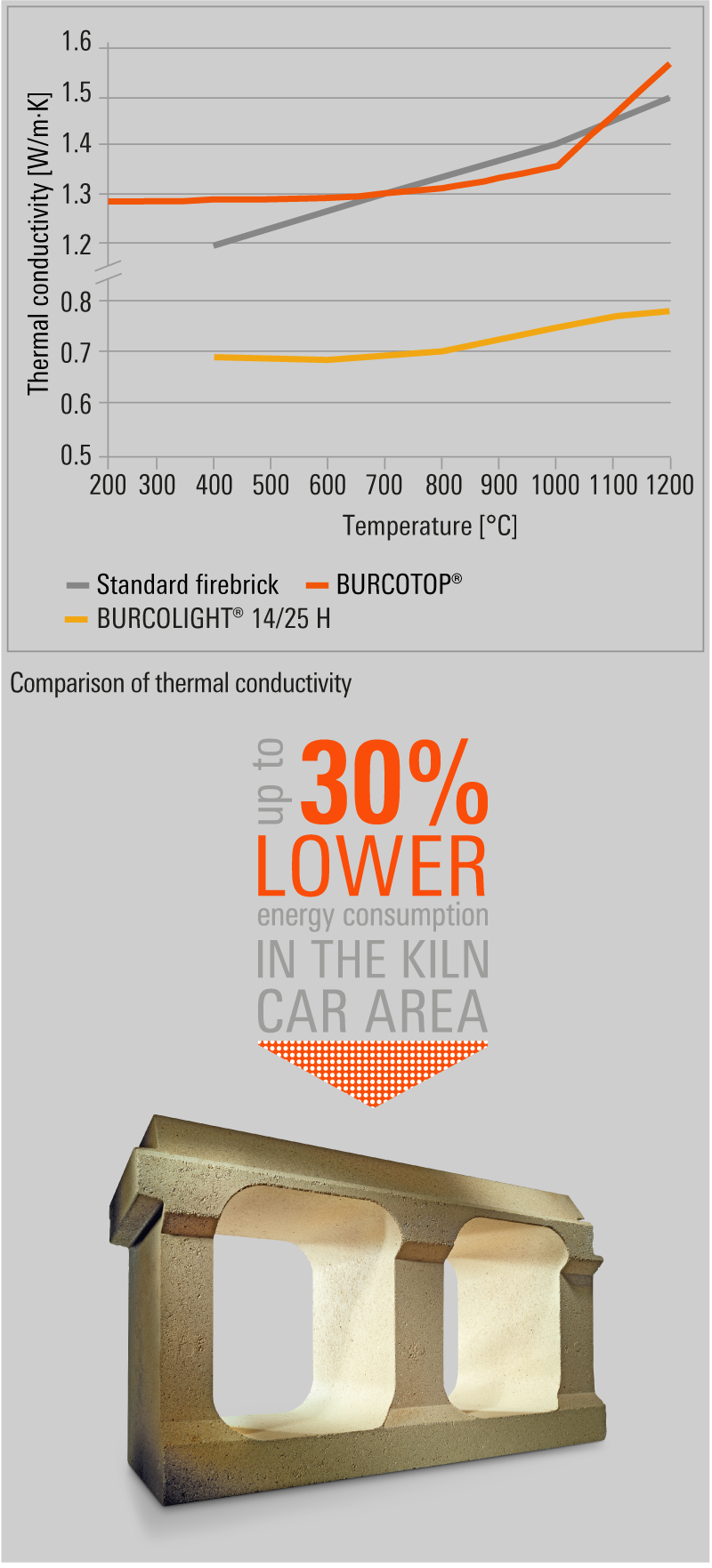

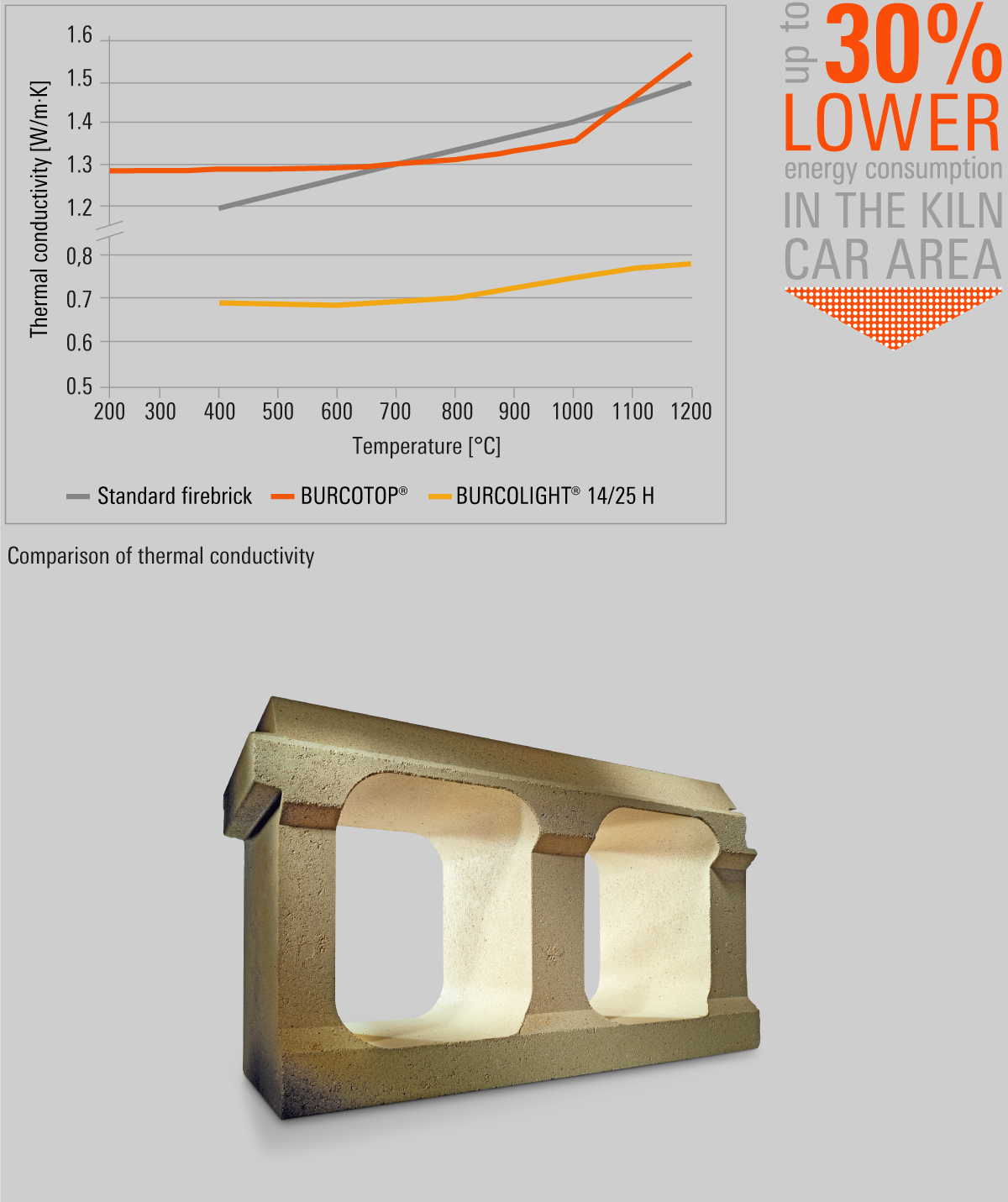

BURCOLIGHT®

Energy saving through weight reduction.

Significantly reduced energy consumption in the kiln car area thanks to lower weight of the refractory materials – BURCOLIGHT® meets this important demand of the ceramics industry. Due to its excellent thermal shock resistance and low thermal expansion, this refractory system is also a decisive safety factor for production.

- up to 30% energy savings in the kiln car area

- bulk density of only 1.3 to 1.5 kg/dm3

- low thermal conductivity and thermal expansion at 1100 °C

- also suitable for short passage times

Ceramics

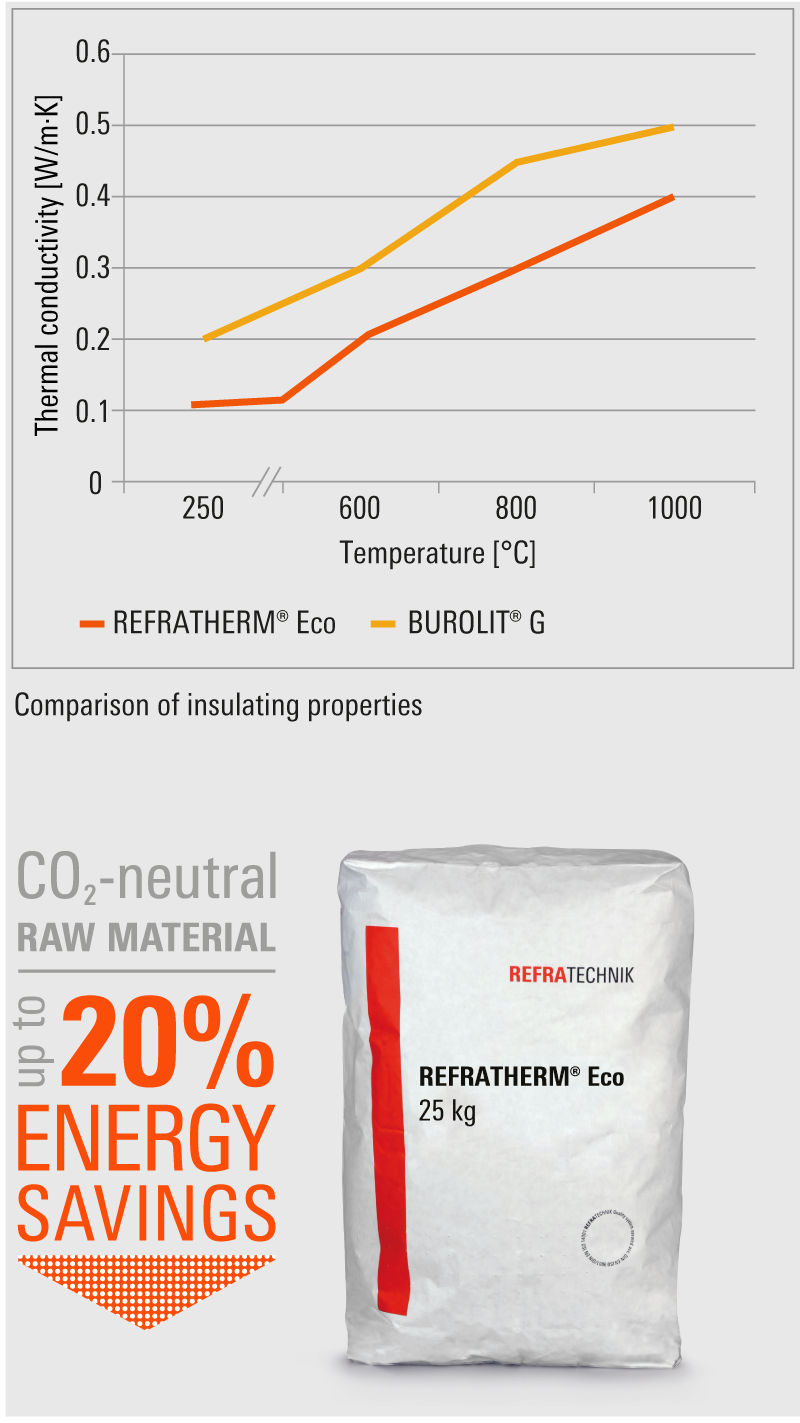

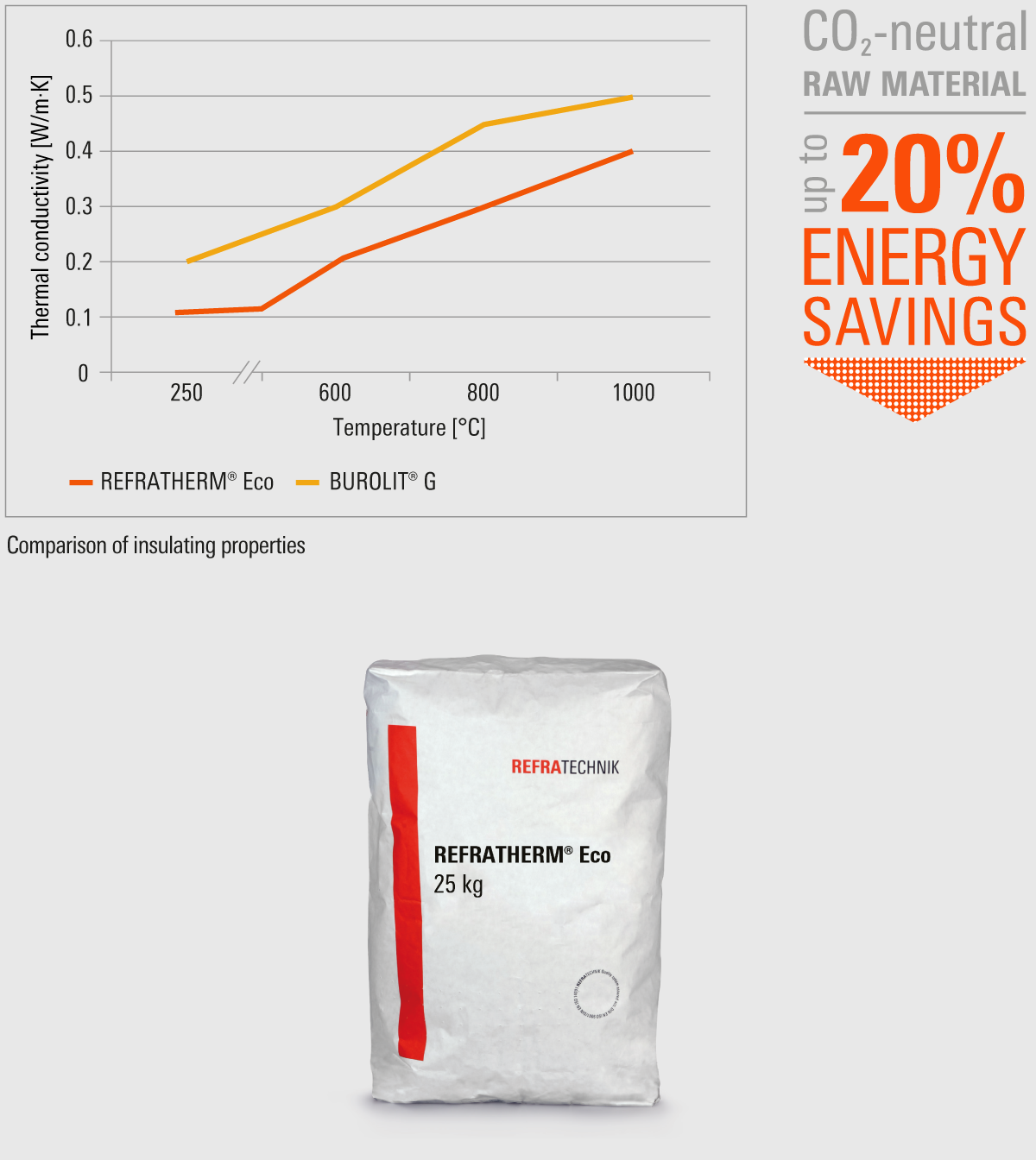

REFRATHERM® Eco

The ideal insulation for kiln cars.

Based on micro-porous silica, REFRATHERM® Eco exhibits a unique combination of outstanding properties. The material features extremely good insulating properties, and the resulting reduction of thermal conductivity is a decisive contribution to cost savings in the kiln car area. It permits very low constructional heights, thereby extending the useful space for the brickmaker. Moreover, the excellent workability of REFRATHERM® Eco enables installation time to be cut drastically.

A sintering temperature of 1550 °C, and a melting point of 1650 °C ensure reliable operation with firing processes in the brickmaking industry.

- up to 20% energy savings

- sintering temperature: 1550 °C

- melting point: 1650 °C

- high micro-porosity for excellent insulation

- low density

- extremely low thermal conductivity

Ceramics

Benefits are programmed

Refratechnik‘s qualified products of the ES-SERIES permit:

- significant overall energy savings

- less emissions

- reduced carbon footprint

- reliable, sustainable production

and all this is achieved - without having to modify the manufacturing process

- without the need for additional investments.