Properties of MgO-C bricks

Due to the high temperatures during use, the bricks go through a process in which many application-relevant properties are changed. All mechanical and physical properties in magnesia carbon bricks depend on the thermal history, meaning their working temperature. In the furnaces, temperature profiles develop from the hot face to the cold side of the lining. Accordingly, the properties of the magnesia carbon wear lining change constantly, from pre-heating until the last charging in the furnace, which causes inhomogeneous properties inside the bricks to be distributed.

Different emissions can be released, particularly during the pre-heating phase of a furnace lined with magnesia carbon bricks.

Easier environmental compliance

Easier compliance with environmental legislation, and increased service life – these were the aims of CERAMAC® development. The pre-fired material reduces smoke generation and the release of particles, while simultaneously improving the mechanical properties.

Increased ladle durability

Following the successful introduction of the REFRAFLEX® bonding, Refratechnik developed the CERAMAC® product range. Hereby, thermally processed MgO-C bricks are involved. Because of the pre-firing temperatures (near the operating temperatures), a partially-ceramic bond is formed, which lends completely new properties to the bricks.

The CERAMAC® brick stands out due to its unique combination of a flexible carbon bond with a stable ceramic bond.

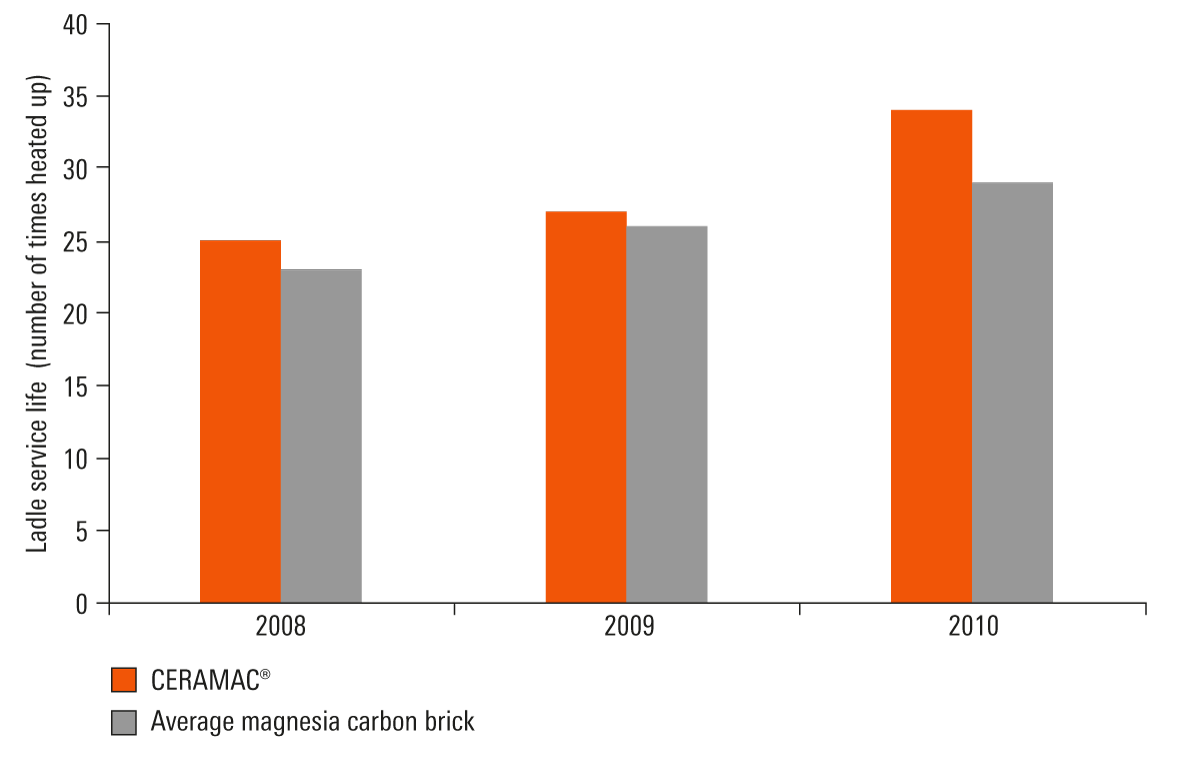

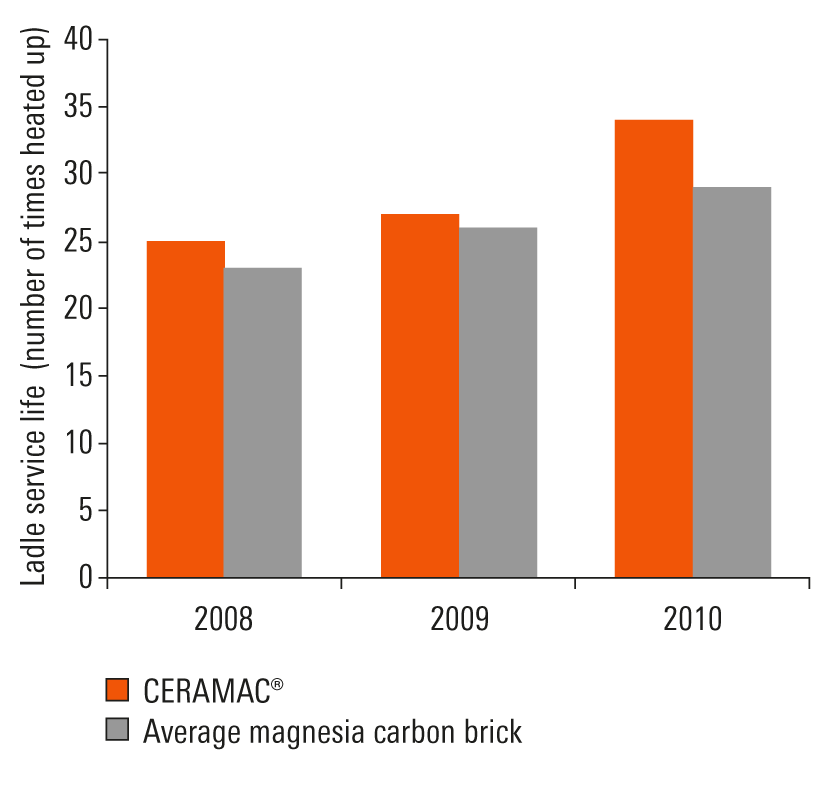

Durability is increased by up to 10%

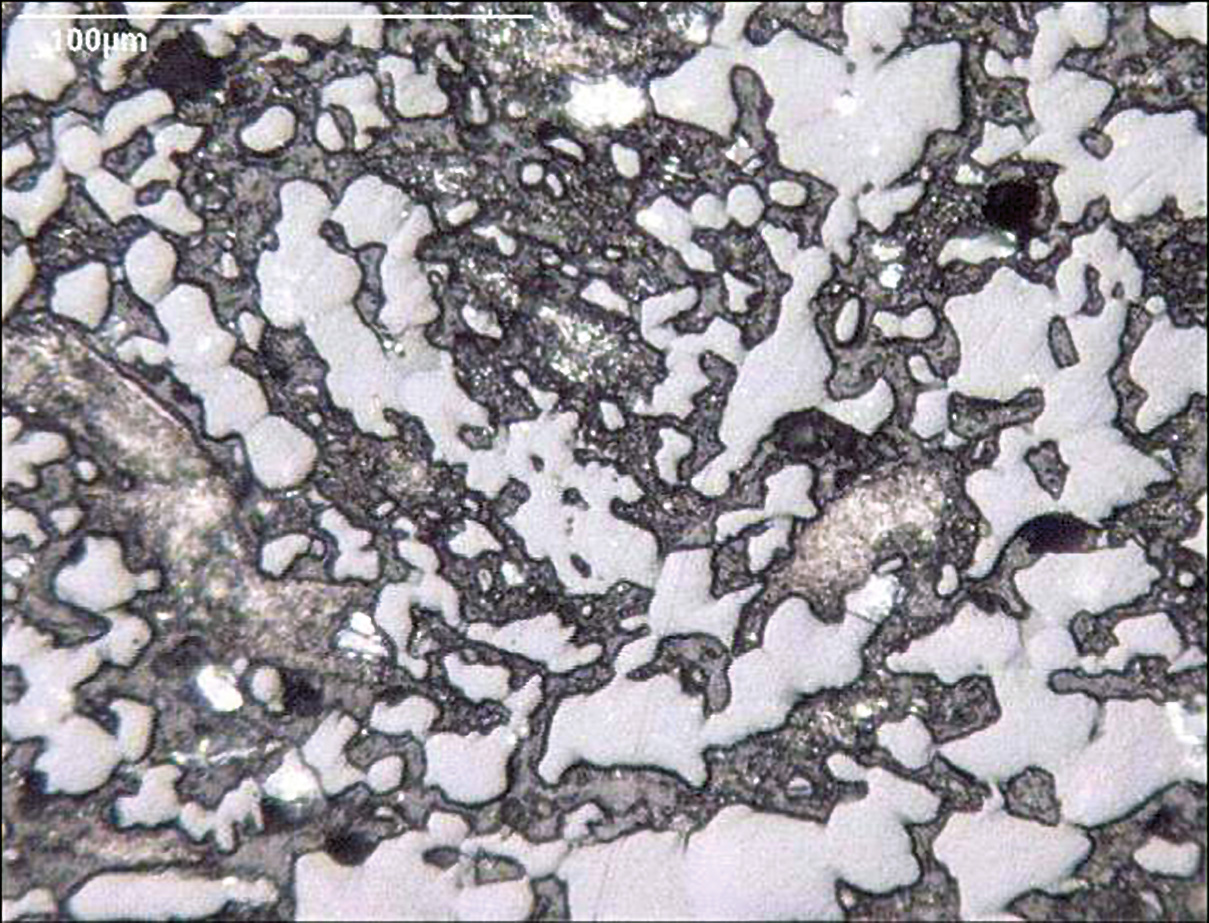

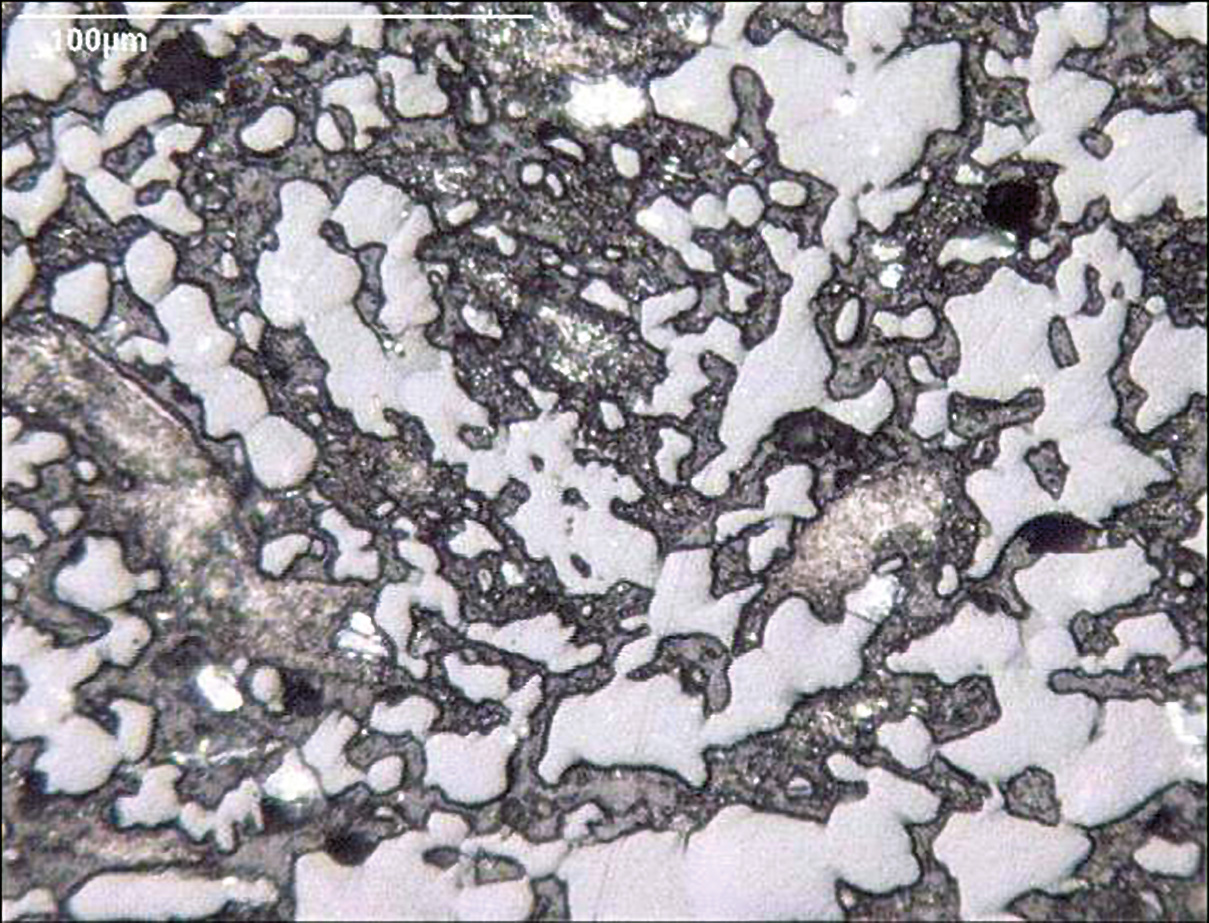

In the process, the bond matrix is graphitized, which has a positive impact on the mechanical properties and the oxidation behavior of the products. Thermal pre-treatment removes all of the volatile components from the bricks so that when they are pre-heated or used, no smoke or odors are released. The CERAMAC® product line has undergone comprehensive testing and has been tried in different standard applications, thus proving its benefits, which include service life increases of up to 10%.

Emission-free pre-heating as well as the increased service life make the CERAMAC® brick one of the most intelligent refractory solutions in steel production.

(Image: Microstructure of a CERAMAC® brick: Magnesia or periclase (light gray) and graphite (dark gray))

Advantages at a glance

- Emission-free heating up

- Durability is increased by up to 10%

- Outstanding service life

- Reduced smoke generation and lower release of particles in the lining concepts

- Cost reduction